Climbing Cranes Would Not Be Possible without Cameras

The Dutch wind turbine manufacturer Lagerwey is the first in the world to develop a climbing crane. The crane is controlled from a laptop on the ground, and 14 Orlaco FAMOS compact cameras play a key role.

It is the end of 2017, and the first part of an L136 wind turbine stands out against the blue skies over the windy harbor of Eemshaven in the Netherlands. Some 60 meters up, a crane system is climbing upward on what will be the tallest onshore wind turbine in the Netherlands (with a tower height of 132 meters and a tip height of 200 meters) at a speed of around two meters per minute. To make this happen, climbing cylinders attach to mounting points on the outside of the turbine mast.

Guided via a Wireless Connection

The crane is controlled from a construction trailer on the ground. The person controlling the crane is even able to walk around. With a control console in hand, the controller steers the crane upwards. Meanwhile, the Lagerwey crane operator keeps an eye on the laptop screen, which displays images from the cameras on the crane via a wireless connection.

Winch View, Load View and Camera Images from Climbing Groups

There are 14 cameras in total — four per climbing group, allowing the operator to check whether each cylinder is properly attached to the turbine mast. There is also a camera that monitors the winch and a camera on the tip of the boom, providing a view of the lifting load when the crane is in position. A dozen presets allow the operator to quickly switch between camera images or bring up images from multiple angles on the screen.

Fully Dependent on Camera Vision in All Conditions

"Those images are crucial. You can't hear, see or feel anything from the ground, so you're really completely reliant on what you see on the screen. This means that the images must be real-time and sharp in all conditions — in bright sunlight or low light, as well as during rain, snow or storms. Orlaco was able to achieve that with its cameras," says Co Kevelam, Lead Manufacturing Engineer at Lagerwey.

Faster and More Secure Lifting Thanks to Improved Visibility

Climbing would not be possible without camera imaging, but there are other benefits too. Orlaco's camera system allows Lagerwey to operate closer to the limit with optimum vision. "For example, imagine that you are lifting the hub, the heart of the blade system, to the top. That hub weighs 50 metric tons. When you're doing this, you need to avoid hitting the turbine mast. With a conventional crane, you'd maintain a safe distance as a precaution and constantly check that everything is running correctly. But now, thanks to camera imaging, we can lift faster and more securely."

Collaborating on Customized Vision Solutions

Mr. Kevelam is the Lead Manufacturing Engineer at Lagerwey and has been closely involved in the development of the climbing crane and the implementation of the cameras. He had close contact with Orlaco throughout this process. "What appealed to me was the can-do attitude, the collaborative thinking and the customization that Orlaco delivers. For example, there are only a few decimeters between the crane and the wind turbine mast. Orlaco therefore proposed a camera with a small aperture angle and a wide image. They then tested whether it would also provide optimum visibility against a white turbine mast," says Mr. Kevelam.

Larger Wind Turbines: A Challenge for Cranes

The wind turbine at Eemshaven is now fully operational, and Lagerwey is currently working on getting the Climbing Crane certified. This year, it should be possible to deploy the crane fully independently, which will put a strong tool in Lagerwey's hands. Wind turbines are increasingly growing larger and taller, which means that there is also need for larger cranes, of which there are only a few in Europe. "That kind of crane arrives on at least 50 trailers, takes several weeks to build and requires a construction site of approximately 3000 m2. This means that construction costs are high and there are restrictions on planning," says Mr. Kevelam.

Benefits of the Climbing Crane with Camera Vision

A crane that "climbs" together with the mast solves those problems. Lagerwey's innovative model fits on three trailers, is operational within half a day and only requires a construction site of 350 m2. As the crane is relatively light and does not have to be supported by the ground, it can also be built in locations that are difficult to reach such as dykes, forests and muddy or hilly terrain.

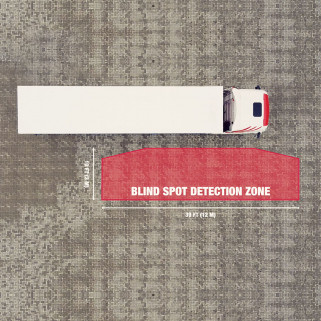

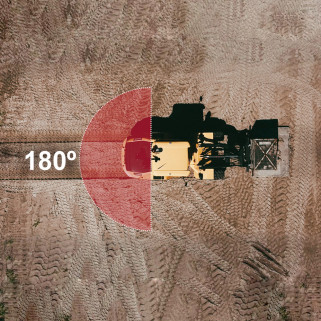

Orlaco Vision Solutions for Conventional Cranes

This is all thanks to some excellent collaboration in Barneveld, the Dutch city where both of these innovative companies are based. Orlaco also offers solutions for conventional cranes, including telescopic cranes, crawler cranes and tower cranes. These camera monitoring systems give the crane operator an optimum view of the blind spots around the crane, the lifting hook and the load in all circumstances.