Cameras and Radars Are Worth Their Weight in Gold in Russian Mega-Mine

Gold mines are among the most challenging working environments in the world. They are places where huge mining vehicles brave harsh conditions every day. This is why PJSC Polyus equips all of its vehicles in the vast Russian Olimpiada mine with cameras, radar and monitors.

It is the heart of winter in the middle of nowhere, 310 miles (500 kilometers) north of the city of Krasnoyarsk in Siberia. It is 49 degrees Fahrenheit below zero (-45°C) and snow is falling, but this won't hold back the hundreds of employees of Russia's largest gold mine. Giant mining vehicles constantly wind their way up the miles of road around the edge of the Olimpiada.

Challenges in One of the World's Largest Gold Mines

Visibility is minimal, and is only getting worse due to the diesel fumes that fill the air. However, from the cab of his dump truck, Aleksandr can see exactly where he is driving — all thanks to Orlaco RadarEye. RadarEye combines camera vision with radar detection of stationary and moving objects to a distance of over 65 feet (20 meters).

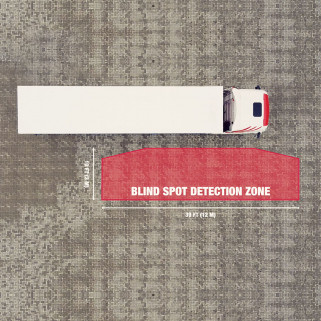

Acoustic Warning Signals and Blind Spot Vision

If Aleksandr gets too close to the verge and the steep edge of the mine road, the system gives out an acoustic warning signal. If he is reversing and someone gets in the path of his dump truck, he will see that on his monitor. It shows a transparent detection zone with overlays of blind spots around the vehicle.

PJSC Polyus: Leading Player in the Global Gold Market

Olimpiada is the largest and most important mine operated by PJSC Polyus. Over 3100 people work at the mine, where a total of 1,173,000 ounces of gold were extracted last year. A total of 28 million ounces of gold are still confirmed to remain under the ground. PJSC Polyus also has huge reserves in other mines, making the company one of the largest gold producers in the world.

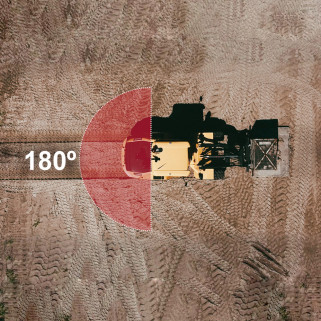

Optimum Vision from the Excavator When Loading the Dump Trucks

With such an impressive fleet of vehicles, not only dump truck drivers benefit from RadarEye. The excavators that load the trucks are also equipped with the system, provided by Orlaco's Russian partner, VIST Group. The operators can now view the engine, cables, dipper and counterweight, all on their monitors. This gives them the control they need to remain flexible in all conditions and keep the constant flow of dump trucks driving up and down the mine filled up.

Drivers Insisted on Installing Cameras and Radars after Pilot

"The worst time of the year is around February and March. There's so much snow and wind that you can barely see anything in the mine. We tried just about everything to resolve the vision problems, but nothing worked — until we tried a pilot with RadarEye. The drivers insisted on having all their vehicles equipped with cameras and radars," a mine spokesperson explains.

Made to Perform in All Conditions

RadarEye is made for unrelenting conditions such as these. Whether it is icy cold, with snowstorms buffeting Olimpiada, or huge dust clouds and extreme heat are pushing operators to their limit, RadarEye never misses a thing. The system is waterproof (IP69), vibration and shock resistant (15 G + 26 G), and, thanks to infrared technology, the camera also provides optimum night vision.

Successful Large-Scale Deployment with Orlaco Partner VIST Group

Following the successful pilot in 2016, all excavators, loaders, dump trucks, bulldozers, pipe layers, motor graders and other mining vehicles have been equipped with the Orlaco system, totaling 1500 cameras and 320 monitors. This was done by VIST Group, Orlaco's Preferred Partner in Russia. Orlaco works worldwide with partners like this, ensuring regional exclusivity to help them strengthen their market position and increase their returns. Orlaco supports its partners by providing product information, marketing materials, demo equipment, and technical and commercial support.

Reduction in Incidents, More Working Comfort for Drivers

Two years later, they are singing the praises of RadarEye in Russia. Since installing the systems, safety in the mine has increased. There have been fewer impacts, collisions and cases of damage, and loaders have not been involved in any incidents at all. This has helped reduce downtime for vehicles and therefore increase efficiency. Drivers say that they no longer have to twist to look behind them while reversing, resulting in fewer physical complaints. There has also been a drop in stress at work thanks to improved vision.

RadarEye Is Coming to More Russian Gold Mines

This is part of the reason why PJSC Polyus is going to equip its vehicles in a second Siberian mine with Orlaco's vision solutions for heavy duty vehicles. Loaders may also receive an additional camera to gain a view of the area beneath the bucket toward the front of the machine. With this, the Russian gold producer is once again demonstrating that it takes mine safety and the working comfort of its employees very seriously.